- AIR TRANSPORTER

- SM-SERIES

- Selective transfer device product and scrap

- Select and resolve problems of products and scraps made at press, existing transfer device (Conveyor belt etc.)

Usage of Air Transporter

- By installing at the bottom part of mold in press or parts where product is falling (or scrap), it blows down to the external direction of press after receiving product (or scrap).

- Able to apply to the fields in need of transportation.

Features of Air Transporter

- Less noise.

- Simple structure and easy installation.

- Able to transport to the upward in accordance with the weight and friction coefficient.(Max. 8˚)

- Convenient re-installation when changing works.

- Able to install the various number of conveying plates in one machine.

- Convenient maintenance.

Application Example

Video

Air Transporter Specification (Pressure 4.5~5.5kg/㎠)

| MODEL | SM12 | SM24 | SM48 | SM100 |

|---|---|---|---|---|

| Mechanical capacity (kg) |

12 | 24 | 48 | 100 |

| Air pressure consumption (l/min) |

12 | 32 | 46 | 130 |

| Noise (db-A) |

68 | 68 | 68 | 69 |

| Maximum stroke length (mm) |

24 | 25 | 26 | 27 |

| Maximum tray weight (kg) |

2.9 | 4.2 | 5.8 | 20 |

| Recommended strokes per minute (spm) |

120 | 110 | 110 | 100 |

| Mechanical weight (kg) |

2.5 | 4.0 | 6.5 | 18.2 |

| Max.chute(trray)weight [kgf] |

2.9 | 4.2 | 5.8 | 20 |

[ ※ 최대 이송판 무게 제품선정기준]

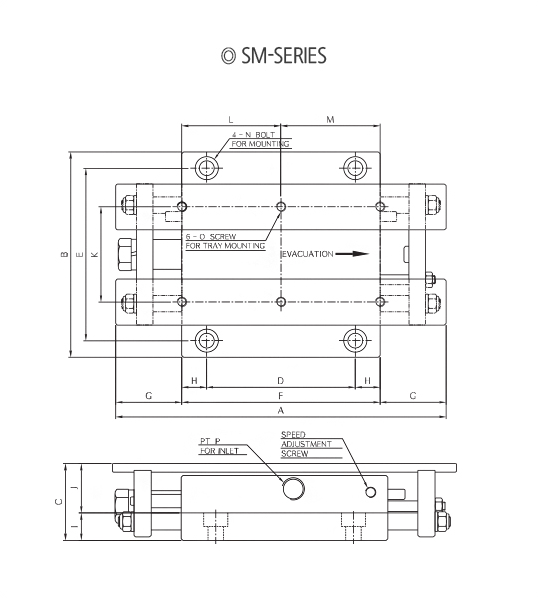

Air Transporter Size

| MODEL | SM12 | SM24 | SM48 | SM100 |

|---|---|---|---|---|

| A mm | 200 | 215 | 240 | 290 |

| B mm | 125 | 140 | 170 | 300 |

| C mm | 46 | 65 | 78 | 102 |

| D mm | 90 | 100 | 100 | 140 |

| E mm | 105 | 120 | 145 | 270 |

| F mm | 120 | 130 | 140 | 180 |

| G mm | 40 | 42.5 | 50 | 55 |

| H mm | 15 | 15 | 20 | 20 |

| I mm | 16 | 20 | 26 | 35 |

| J mm | 30 | 45 | 52 | 67 |

| K mm | 58 | 70 | 85 | 200 |

| L mm | 60 | 65 | 70 | 90 |

| M mm | 60 | 65 | 70 | 90 |

| N | M8 | M8 | M10 | M10 |

| O | M6 | M8 | M8 | M8 |

| P | 1/4" | 1/4" | 3/8" | 3/8" |

※ These specifications and dimensions are for reference only.

And these are subject to change without prior notice depending on the product development process of our company.

※ If processing of the assembly is required, be sure to check the actual size of the product for the relevant.

Outside View

Precautions of Air Transporter

- It shall be operated after installation of AIR UNIT (Filter-Regulator-Lubricator SYSTEM)

- Recommended air pressure: 3~6kg/㎠

- Recommended air temperature: 0~60℃

- Recommended operating time: 8 hour/1 day (Warranty period : 12 months from date of purchase)

- A drop of oil is supplied per minutes through Lubricator,

[ ※ Slide-way fluid or hydraulic oil is supplied: Volatile oil such as WD-40, sewing machine oil and press oil shall not be used x ] - Prohibit to use tray (transport panel) with heavy weight.

- Prohibit to use at over speed.