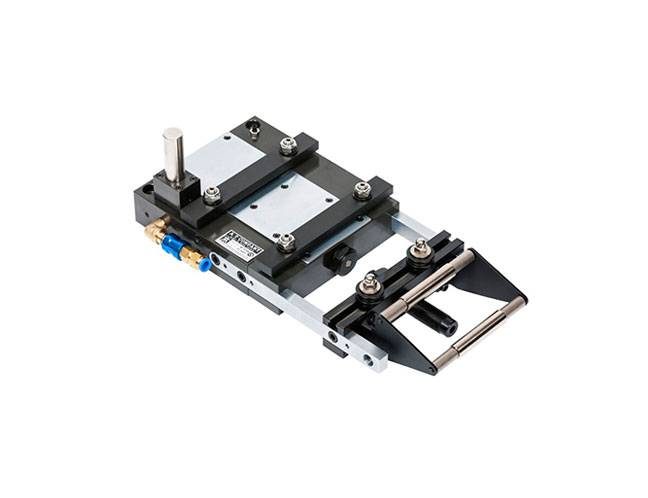

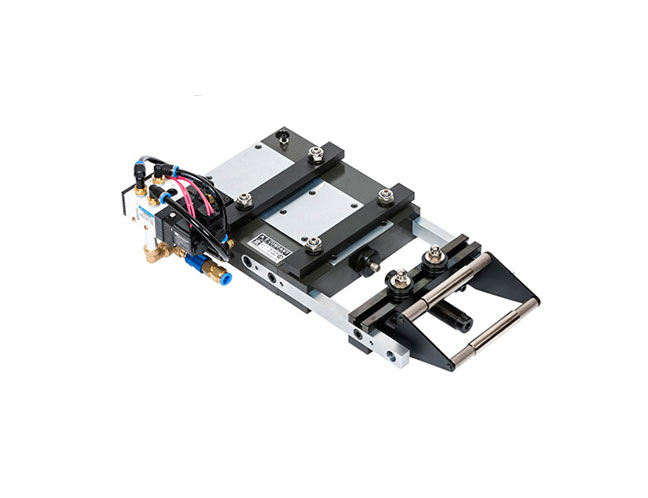

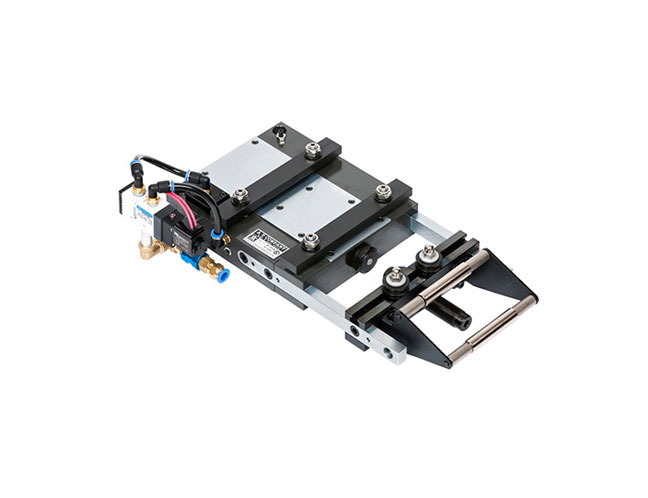

- AIR FEEDER

- AF-SERIES

- Automatic supply device for press materials

- Transfer flat and thin boards at precise allowance

±0.025(mm) supplied to press etc.

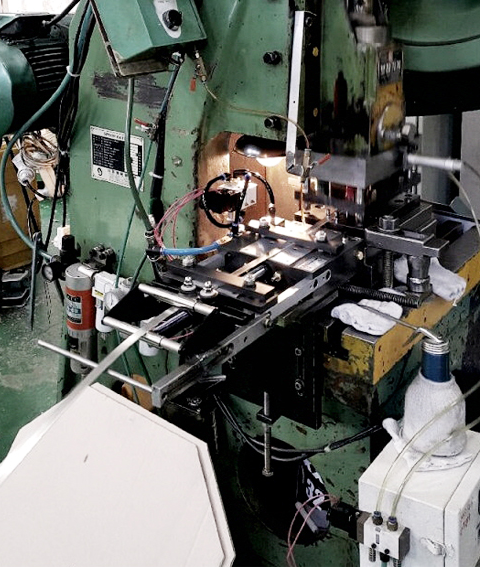

Usage of Air Feeder

- Supply automatically the thin board mainly in the field of press.

- Able to apply to the thin board with figure and to the works of which specific measurements are required.

- Available to simple cutting works.

Features of Air Feeder

- Transport accuracy ±0.025mm

- Able to provide feed of transport by spool valve.

- Reduce the material and weight according to the method of downward piston

- Maintain the degree of precision and reduce noise since there is pneumatic buffer.

- Able to choose push or press with one machine.

- Improve SPM by choosing compress type pilot valve.

- Reduce air consumption by using compress type cylinder.

Application Example

Video

Air Feeder Specification

| Model | AF-0405 S | AF-0415 S | AF-0607 S | AF-0620 S | AF-1010 S | AF-1015 S | AF-1030 S | AF-1515 S | AF-1530 S | AF-2020 D | AF-2515 D | AF-2525 D | AF-3016 D | AF-3030 D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Maximum material width (mm) |

40 | 40 | 60 | 60 | 100 | 100 | 100 | 150 | 150 | 200 | 200 | 250 | 300 | 300 |

| Maximum feed length (mm) |

50 | 150 | 70 | 200 | 100 | 150 | 300 | 150 | 300 | 200 | 150 | 250 | 160 | 300 |

| Maximum material tickness (mm) |

1.2 | 1.2 | 2 | 1.0 | 2.3 | 1.8 | 1.4 | 2.3 | 1.8 | 2.3 | 2.3 | 2.5 | 2.5 | 2.5 |

| Maximum air pressure (kg/㎠) |

within 4~5 | within 4~5 | within 5~6 | within 5~6 | within 5~6 | within 5~6 | within 5~6 | within 5~7 | within 5~7 | within 5~7 | within 5~7 | within 5~7 | within 5~7 | within 5~7 |

| Strokes per minute (Max.SPM) |

200 | 60 | 200 | 50 | 165 | 150 | 50 | 120 | 45 | 60 | 110 | 60 | 90 | 50 |

| Fixed clamp pressure (kg) |

60 | 60 | 122 | 122 | 158 | 158 | 198 | 198 | 366 | 366 | 366 | 492 | 647 | 647 |

| Mobile clamp pressure (kg) |

60 | 60 | 122 | 122 | 158 | 158 | 198 | 198 | 366 | 366 | 366 | 492 | 647 | 647 |

| Tensile stength (kg) |

17 | 17 | 33 | 33 | 47 | 47 | 63 | 63 | 82 | 126 | 126 | 163 | 163 | 163 |

| Air consumption (ℓ/min) |

32 | 26 | 78 | 48 | 124 | 124 | 145 | 178 | 254 | 376 | 310 | 423 | 350 | 363 |

| Product weight (kg) |

3.2 | 4.2 | 5.2 | 7.5 | 10.8 | 12 | 20 | 17.2 | 25 | 32.2 | 31 | 49.6 | 52 | 65 |

※ Max.SPM corresponds to the push type. The pull type is within 50% of Max.SPM of the push type.[It depends on the strokes(feed distance).]

※ All products in the above table should be used with uncoiler(or reel stand)

※ When using the electric type, connect with the solenoid valve according to the air ciruit provided by our company.

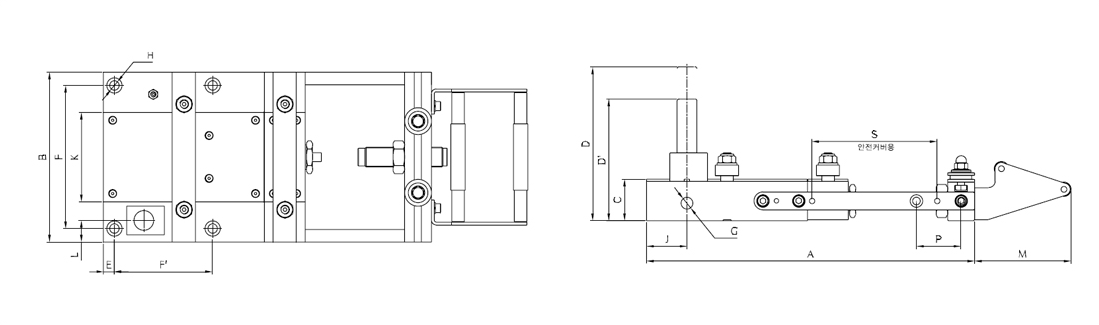

Air Feeder Size

| MODEL | AF-0405 S | AF-0415 S | AF-0607 S | AF-0620 S | AF-1010 S | AF-1015 S | AF-1030 S | AF-1515 S | AF-1530 S | AF-2020 D | AF-2515 D | AF-2525 D | AF-3016 D | AF-3030 D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A (mm) | 223 | 424 | 279 | 540 | 367 | 460 | 772 | 472 | 815 | 614 | 516 | 738 | 588 | 859 |

| B (mm) | 98 | 98 | 136 | 136 | 190 | 190 | 200 | 248 | 270 | 320 | 375 | 390 | 460 | 460 |

| C (mm) | 39 | 39 | 41.5 | 41.5 | 46.5 | 46.5 | 51.5 | 51.5 | 56.5 | 56.5 | 56.5 | 62 | 62 | 62 |

| D (mm) | 120 | 120 | 167 | 167 | 172 | 172 | 205 | 205 | 210 | 210 | 210 | 215 | ||

| D' (mm) | 99 | 99 | 131 | 131 | 136 | 136 | 160 | 160 | 165 | 165 | 165 | 170 | ||

| E (mm) | 8.5 | 8.5 | 10 | 10 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 65 | 12 | 49.5 |

| F (mm) | 76 | 76 | 114 | 114 | 160 | 160 | 170 | 220 | 230 | 280 | 335 | 282 | 400 | 345 |

| F' (mm) | 100 | 125 | 200 | 125 | 200 | 170 | 135 | 205 | 150 | 260.5 | ||||

| G (PT) | 1/8" | 1/8" | 1/8" | 1/8" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 3/8" | 3/8" | 3/8" |

| H (mm) | 2-C/B M8 | 2-C/B M8 | 2-C/B M8 | 2-C/B M8 | 2-C/B M10 | 2-C/B M10 | 4-C/B M10 | 4-C/B M10 | 4-C/B M10 | 4-C/B M10 | 4-C/B M10 | 4-C/B M10 | 4-C/B M10 | 4-ø12.5 HOLE |

| J (mm) | 30 | 30 | 38 | 38 | 45 | 45 | 50 | 50 | 55 | 55 | 55 | 85 | 50 | 90 |

| K (mm) | 40 | 40 | 60 | 60 | 100 | 100 | 100 | 150 | 150 | 200 | 250 | 250 | 300 | 300 |

| L (mm) | 17 | 17 | 20 | 20 | 24 | 24 | 28 | 28 | 35 | 35 | 35 | 45 | ||

| M (mm) | 26 | 26 | 82 | 82 | 108 | 108 | 122 | 122 | 142.5 | 142.5 | 142.5 | 186.5 | 186.5 | 186.5 |

| P (mm) | 30 | 50x2 | 35 | 50X3 | 50 | 50 | 75X3 | 50X2 | 75X3 | 70X2 | 80 | 80X2 | 80 | 100X2 |

| S (mm) | 90 | 235 | 110 | 315 | 140 | 180 | 435 | 250 | 450 | 320 | 270 | 400 | 320 | 460 |

- Specifications and size may be changed without notification due to product development.

- Above models are fundamental models. Other models are produced upon order.

- Start air feeder after installing the air unit.

※ These specifications and dimensions are for reference only.

And these are subject to change without prior notice depending on the product development process of our company.

※ If processing of the assembly is required, be sure to check the actual size of the product for the relevant.

※ Other models which are not in the list of specification shall be produced after discussion.

Outside View

Precautions of Air Feeder

- Operate Air Feeder after installation of AIR UNIT (Filter-Regulator-Lubricator SYSTEM)

- Recommended air pressure: 3~6kg/㎠

- Recommended air temperature: 0~60℃

- Recommended operating time: 8 hour/1 day (Warranty period : 12 months from date of purchase)

- A drop of oil is supplied per minutes through Lubricator,

[ ※ Slide-way fluid or hydraulic oil is supplied: Volatile oil such as WD-40, sewing machine oil and press oil shall not be used x ] - Never do not place any part of the body near the pilot (operating switch) when compressed air is being input (or product operating).

- All products in the above table should be used with uncoiler(or reel stand)

- When using the electric type, connect with the solenoid valve according to the air ciruit provided by our company.